Rise from the Ashes: The Journey of Monir Hossen and Habib Engineering Workshop

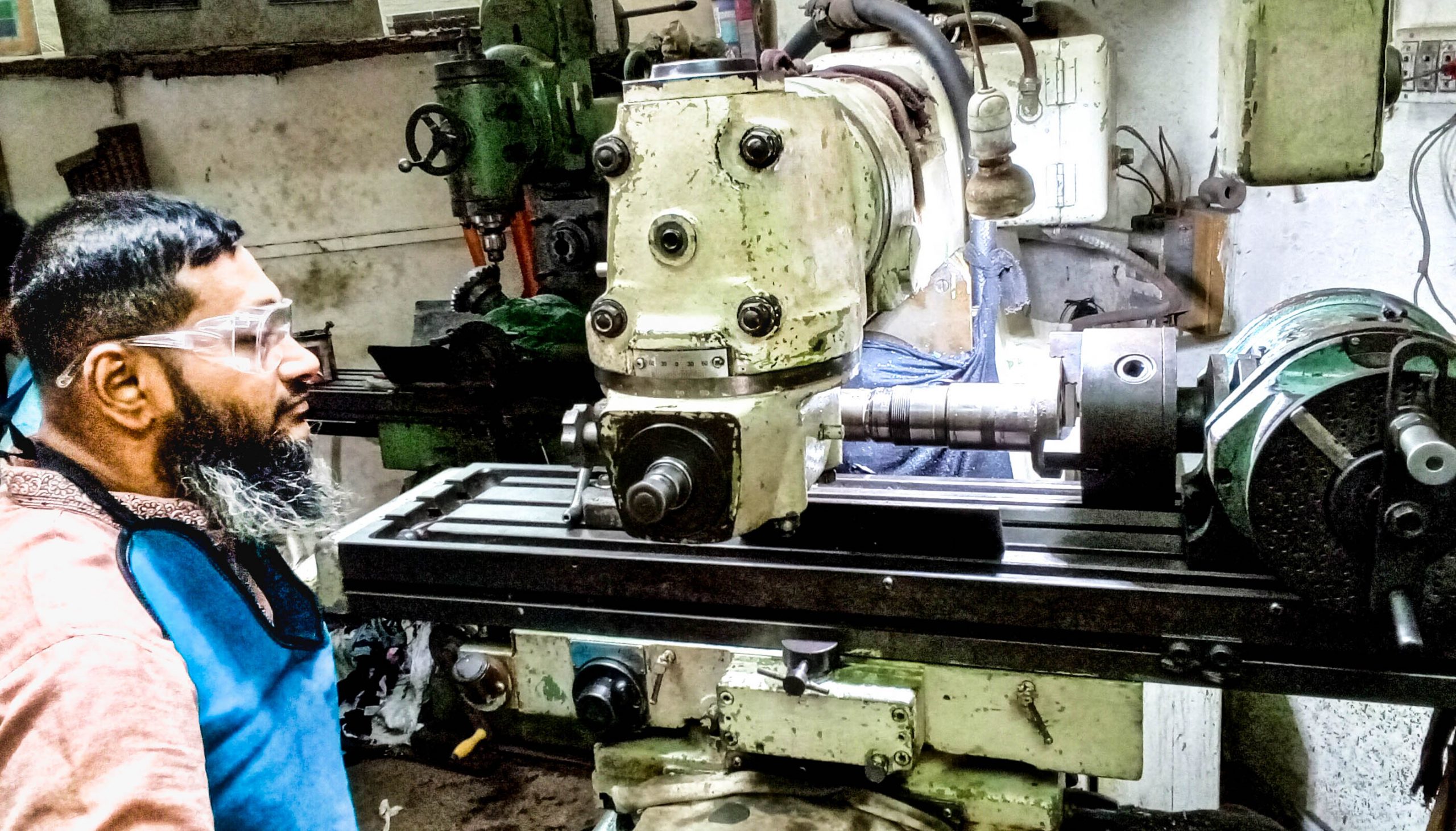

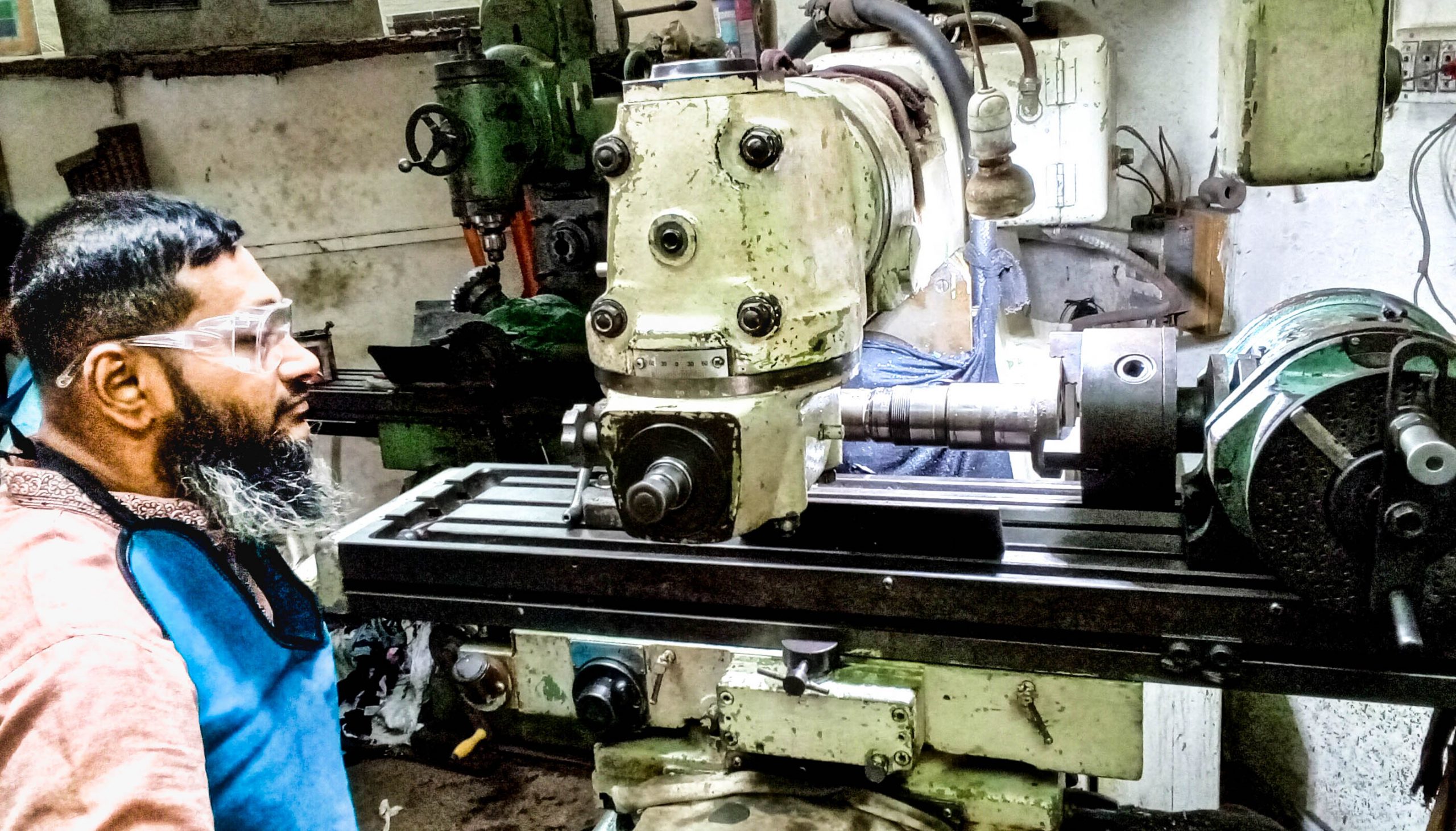

Monir Hossen, a quintessential struggler, came to Narinda, Old Dhaka, with dreams of making a name for himself. He had a passion for machinery and tools, and knew that this was his calling. Despite the hardships, he never let go of his dreams. Monir first ventured into the business of making dice, but unfortunately, the business couldn’t see the light of success. Undeterred by this initial failure, he pivoted his focus towards manufacturing different types of machinery spare parts.

Previously, his workshop efficiently handled a diverse workorder of 2000 pcs of Pinium, and earned the revenue of 275,000 BDT with 7% of profit margin. The Covid-19 pandemic hit businesses hard across the globe and Habib Engineering Workshop was no exception. Monir found himself in need of substantial capital to buy a new Vertical Milling machine. However, his fortunes took a significant turn for the better after receiving the common service loan from BASTOB, which proved to be a game-changer for his business. Now he efficiently handles 3000 pcs of dice or more, and his revenue has surged to an impressive 364,000 BDT. His profit margin has surged to an impressive 10%, representing a commendable 3% increase.

Over time, Habib Engineering Workshop grew, supplying spare parts primarily to mills and factories. The workshop now houses five lathe machines, three VMCs, and two milling machines, operated by a team of 15 dedicated workers and three trainees. As part of the loan agreement and SEP team guidance, Monir committed to improving his workshop’s conditions. The SEP team ensured Personal Protective Equipment (PPE), safe drinking water, a first aid box, fire safety measures, and a waste bin were available in his workshop. With technical assistance from the SEP team, he introduced ventilation, a proper storage system, and ensured appropriate wiring.

SEP also provided Monir with opportunities to attend several workshops and training programs. These included Environmental certification training, Use of Modern Machineries, Accounts and Business Management Training, a Workshop with Relevant Authorities, and a Workshop on Uncertified Chemical Use. Monir seized these opportunities to enhance his skills and knowledge, stating,

His story serves as a beacon of hope and inspiration for others, proving that with hard work and the right opportunities, anyone can rise from the ashes and achieve great success.